Specificities of hydraulics machined parts

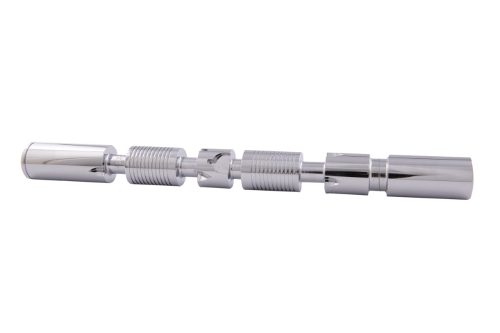

Our know-how enables us to produce hydraulic systems components, with complete control of the clearances and geometries necessary for their perfect functioning. For example: hydraulic valves with lengths of up to 300mm diameter, tolerances of 5 microns, straightness tolerances of 5 microns, roughness of 0.8 and concentricity of less than 5 microns

Because all hydraulic parts are subjected to long life with a lot of wear and tear, this is a highly technical sector of activity, necessitating:

- heat treatment, to harden the component

- rectifying the parts which may have been deformed by the heat treatment

- controlling a complete absence of burrs and a high level of cleanliness.

Examples of our machined parts

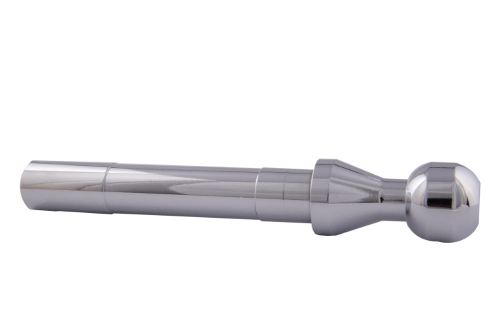

For lifting equipment we produce:

- Hydraulic pistons used in control joysticks for caterpillar tracks and for mechanical digger arms, in ETA 100, plus TTH and rectification.

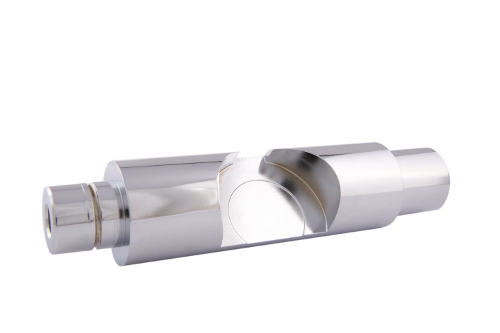

For hydraulic pumps we produce:

- Machine finished hydraulic vanes, with masked TFS milling, used to calculate fluid flow.

Valves for the opening and closing of pumps.

For agricultural vehicules we produce:

- Motor transmission axels.